Beer Filtration for craft brewers

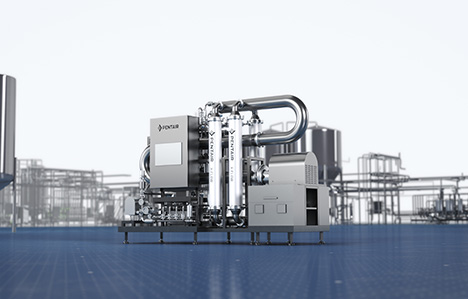

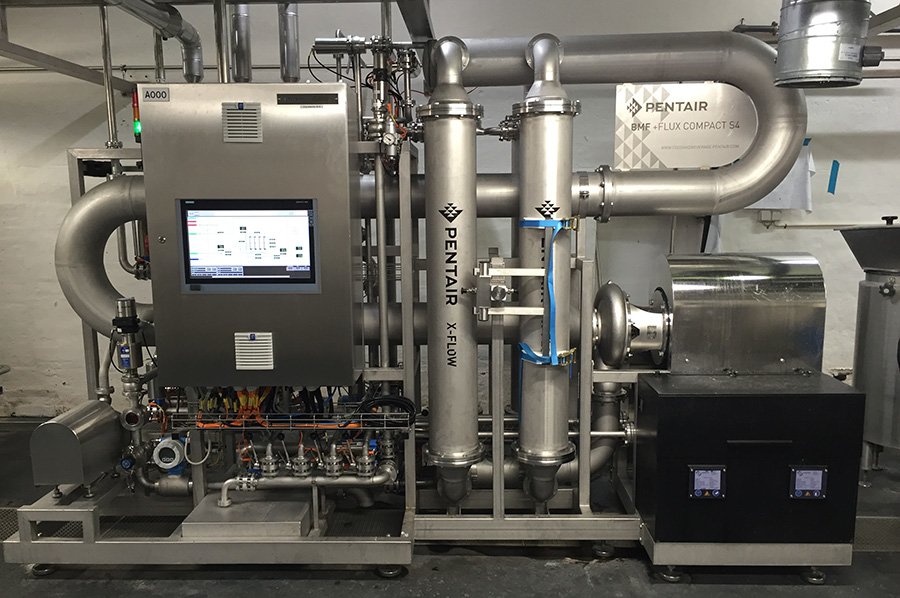

The Pentair BMF +Flux Compact S4 is a fully automated beer membrane filtration system tailored for batch processing in small and craft breweries.

Designed to handle capacities between 30 and 80 hectoliters per hour, it delivers exceptional beer clarity, flavor stability, and operational efficiency, without the need for diatomaceous earth.

This compact system helps you reduce beer loss, cut down on waste, and improve sustainability, all while maintaining the flexibility and control that smaller breweries need.

Benefits

- Perfect for Batch Brewing – Designed specifically for small-scale, flexible production.

- Minimize Beer Loss – Reduce product loss to as low as 0.5%.

- Sustainable Brewing – Lower waste disposal and energy use.

- Compact & Scalable – Small footprint with options to expand capacity.

- Smart Automation – Fully automated with intelligent process control.

- Remote Support – Access diagnostics and support from anywhere.

- User-Friendly Interface – Simple start-stop system for easy operation.

- Modular Add-Ons – Easily integrate with Pentair’s CarboController (CCR) and CarboBlender (CBR) for carbonation and blending.

-

Features

-

- Based on Pentair X-Flow Hollow Fiber Membrane Technology.

- Integrated Südmo Process Valve Technology.

- Inline cleaning.

-

Service You Can Count On

-

We crafted our SLA packages to provide greater peace of mind in knowing that your Pentair BMF System is being monitored and used to its full potential. 24/7 technical support.

- Lifetime module cover

- Pentair Q

- Monthly touchpoints

- Bi-weekly optimization touchpoints

- 24/7 virtual & phone support

- Root cause analysis

DOWNLOADS

| TITLE | DOWNLOAD PDF | |

| Leaflet | BMF +Flux Compact S4 | Download |

| Product Overview Brochure | Beer Membrane Filtration from Pentair | Download |

| Case study | Princen Brewery (English) | Download |

| Case study | Princen Brewery (Portuguese) | Download |

| Case study | Jacobsen Craft Brewery (English) | Download |

| Case study | Brewery St. Austell (English) | Download |

| Brochure | BMF Service Level Agreements (English) | Download |

| Technical Documentation | Request Product-Specific Technical Documentation | Send Us Your Request |

Related Products

Beer Membrane Filtration System for craft to small-sized breweries that produce at a capacity between 80-170 hl/hr.

Turnkey filtration solution for breweries with capacity 7,000–22,000 hl/d.

CARBONATION AND BLENDING SYSTEM - CARBO BLENDER - CBR

Pentair Haffmans’ Carbo Blender combines accurate control of both blending and carbonization in one skid-mounted unit.

Beer Membrane Filtration System for mid-size breweries that produce at a capacity between 150-250 hl/hr.

Beer Membrane Filtration System for large breweries that produce at a capacity between 200-900 hl/hr.

CARBONATION CONTROL SYSTEM - CARBO CONTROLLER - CCR

The Carbo Controller works by injecting CO2 at the inlet of a dissolution tube. Combined with the reliable O2 measurement, this enables you to achieve total process control.

BEER STABILIZATION SYSTEM - BEERSTAB

The most straightforward, user friendly beer stabilization system, ensuring what you need: stable beer.

Featured cases

Eliminating Kieselguhr

Jacobsen Craft Brewery, Denmark

Replacing DE Filtration with Automated Membrane Technology

De Hollandse Pilsener Fabriek, The Netherlands

Advancing Filtration for Quality, Sustainability, and Kieselguhr-Free Brewing

St. Austell Brewery, United Kingdom

- Hero4

- Hero4

- Hero4