CAPTURE AND UTILIZE VALUABLE CO2

Don’t let your CO2 by-product stream become a waste gas vented into the atmosphere. Worldwide demand for CO2 is growing for use in beverage carbonation, food preservation, or when creating fertilizers, for example. Opportunity awaits commercializing this waste gas through purification in a CO2 recovery plant.

Patented CO2 purification technology

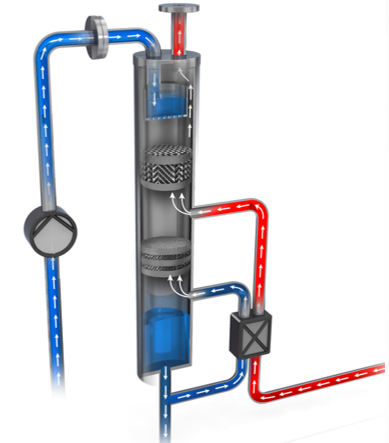

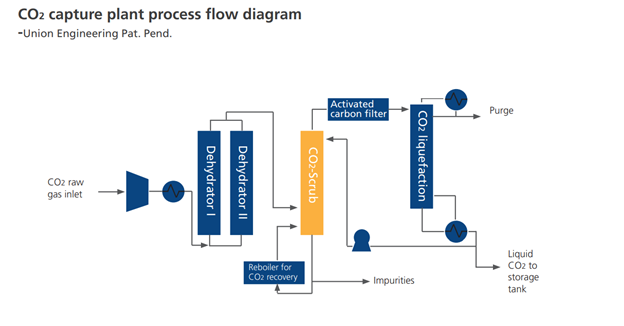

Pentair CO2Scrub is an innovative purification solution that maintains product quality at varying feed gas compositions.

Our patented technology removes impurities at a high boiling point, including aromatic components, alcohols, oxygenates, terpenes, and some sulfur components, as is typically present in gasses from fermentation, anaerobic digestion, and some industrial processes. Compared with other CO2 purification solutions that use drinking water as the purification medium, Pentair CO2Scrub is a water-free purification solution, helping to reduce its impact on our environment.

Commercial opportunity awaits to produce food-grade quality CO2 while sustainably reducing your emissions.

PENTAIR CO2SCRUB

Pentair CO2Scrub

Removal of impurities capabilities of the Pentair CO2Scrub 1.0 & the CO2Scrub 2.0 versus water scrubbing.

-

FEATURES

-

- Eliminates impurities with a boiling point above – 30 degrees Celsius.

- Efficient carbonyl sulfide (COS) removal

- Configured as a packed column to minimize the amount of liquid CO2 used in the scrubbing process.

- Losses of liquid CO2 are minimized by re-boiling.

-

BENEFITS

-

- Minimizes the need for carbon filters, water scrubbers, and other purification steps

- Energy optimized

- Flexible process to adapt to varying impurity levels, also after installation

- Excellent system for final CO2 polishing

- Possible replacement of regenerable activated carbon beds

- Possible replacement of water scrubber nits

- Continuous replacement of absorbent - not needed

- Tolerant for varying hydrocarbon content in the raw gasNo use of additional external sources is eliminating the risk of contamination

- Reduced amount of waste

- No use of water

DOWNLOADS

| TYPE | SUBJECT | |

| Product leaflet | CO2Scrub | Download |

| Technical documentation | Looking for operating instructions, installation manual, spare part list etc.? | Please, send us your request |

RELATED PRODUCTS

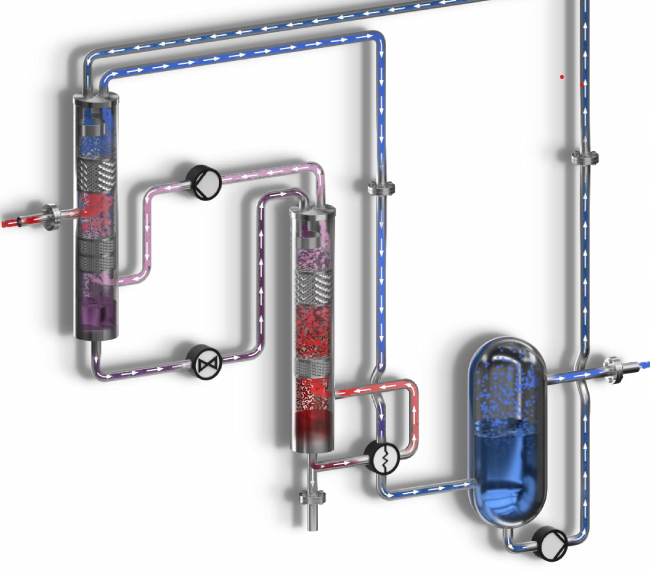

Pentair Recovery Based Unit - RBU Plant

Capture, liqueaction and purification of high purity CO2 raw gas.