- Home

- Case Studies

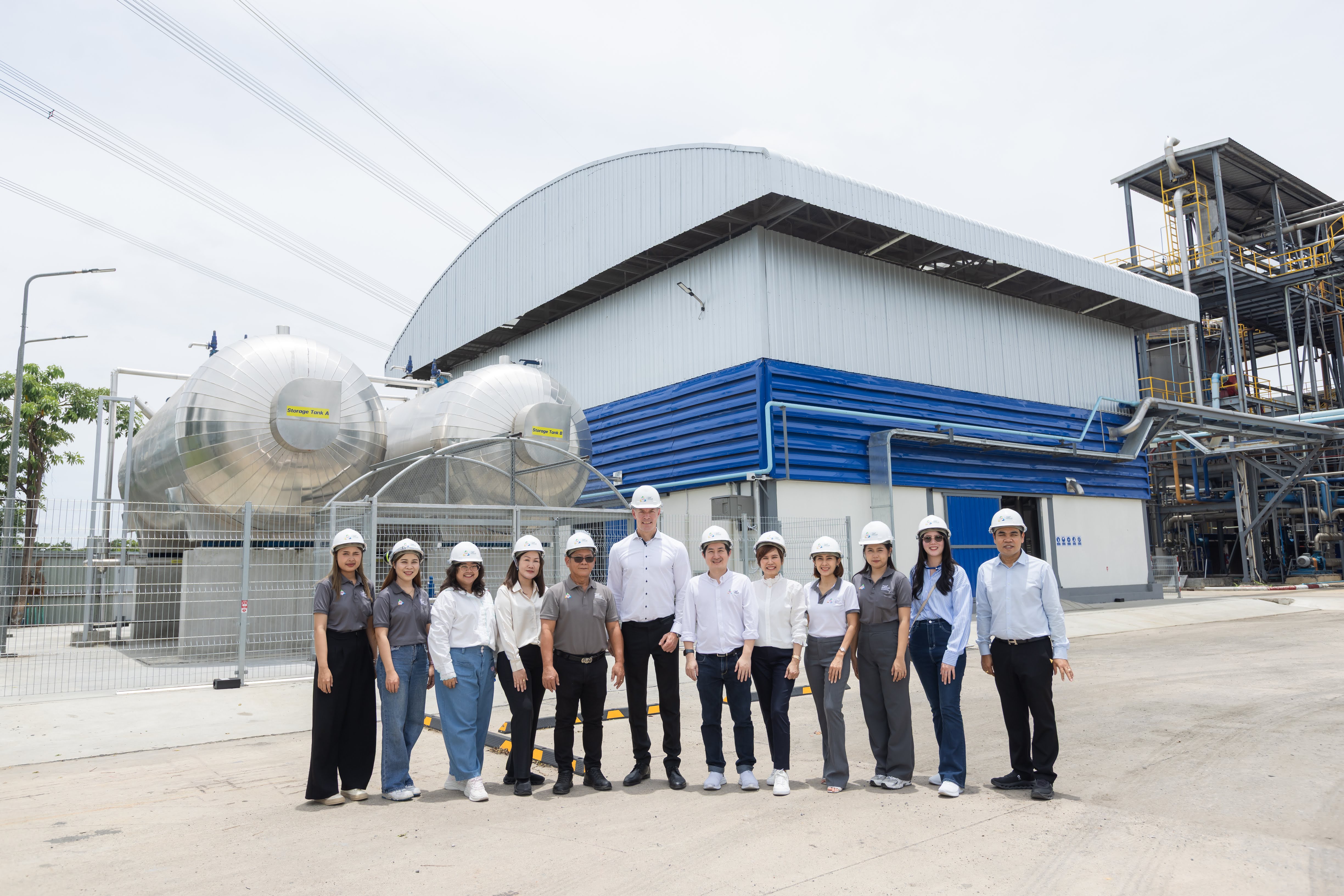

- Thai Sugar Mill Group

Industry

Agro-industrial sector

Challenge

Reduce CO₂ emissions generated from molasses fermentation—a byproduct of sugar manufacturing.

Solution

Pentair Recovery Based Unit (RBU)

Results

Has a capture capacity of 48 tons of CO2 per day.

Background

Thai Sugar Mill Group (TSM Group), a leading sugar producer in Thailand, is committed to building a sustainable society for future generations. Their operations are deeply rooted in circular economy principles, aiming to maximize the value of natural resources while minimizing environmental impact.

As part of their ethanol production process, TSM Group sought a way to capture and repurpose the CO₂ emissions generated from molasses fermentation—a byproduct of sugar manufacturing. Their goal was to reduce greenhouse gas emissions and create a sustainable CO₂ source for industrial use.

THE SOLUTION

TSM Group partnered with Pentair via our distributor, I-Born Supply and Service Ltd., to implement the first bio-CO2 capture plant in the Thai sugar industry.

The plant recovers raw CO₂ from the sugarcane molasses fermentation process and purifies it for industry reuse. This plant is a key component of TSM’s circular economy strategy, turning waste into value while promoting environmental stewardship.

The raw gas from fermentation contains a high concentration of CO₂ (typically 95–99%) but may also include impurities such as hydrocarbons, NOx, sulphur compounds, alcohols, and oxygenates. To address this, Pentair designed a highly customized plant in close collaboration with TSM, optimizing both capital and operational expenditures.

The purification process integrates several proprietary and patented Pentair technologies, including the Pentair CO₂ Scrub system. Unlike conventional CO₂ purification methods that rely on water, the CO₂Scrub uses a completely water-free process, significantly reducing environmental impact. It effectively removes high-boiling-point impurities, ensuring the final product exceeds food-grade CO₂ standards.

The Impact

TSM Group’s adoption of bio CO₂ capture reflects a growing commitment to sustainable industrial practices in Southeast Asia. The plant helps reduce greenhouse gas emissions and aligns with Thailand’s broader climate goals. With an initial production capacity of 48 tons per day and plans for future expansion, TSM is preparing to meet the growing demand for sustainable CO₂ both locally and internationally.

Related Products

Pentair Recovery Based Unit - RBU Plant

Capture, liqueaction and purification of high purity CO2 raw gas.

Union Engineering Advanced Amine Technology Plants - AAT

Capture CO2 from any gas stream based on the combustion of fossil fuels.

NEWS