CO₂ Recovery for Large Breweries

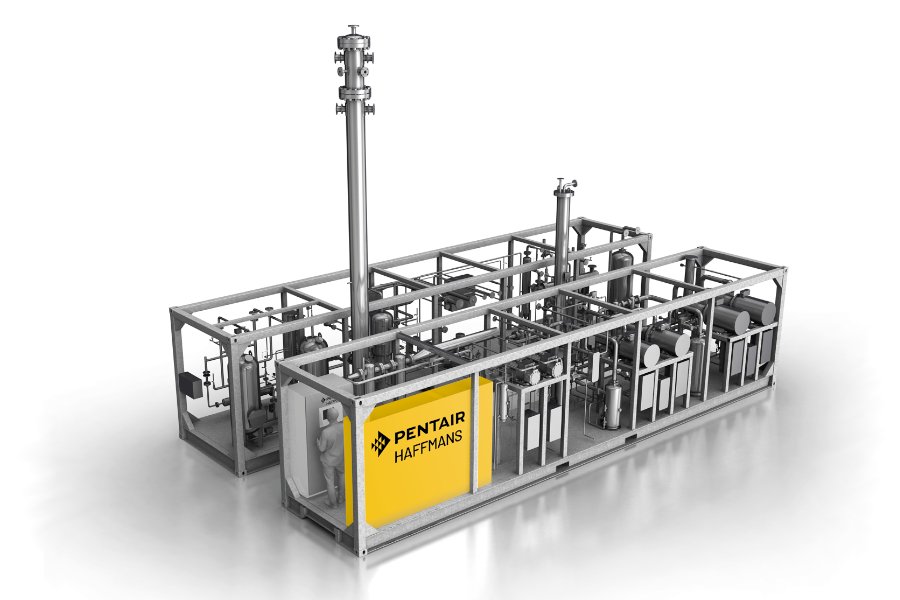

Haffmans ECO₂Brew is designed for high-capacity breweries operating 24/7 (>2,000,000 hl/year) to recover CO₂ from fermentation processes efficiently and sustainably. With 100% water-free operation, ECO₂Brew saves up to 1 m³ of water per tonne of liquid CO₂, reducing resource consumption and operating costs.

Maximum Recovery, Zero Water Consumption

At the heart of ECO₂Brew is Pentair’s proprietary CO₂Scrub technology, a breakthrough in gas purification.

Unlike traditional systems, CO₂Scrub removes impurities from fermentation gas without consuming water, saving up to 1 m³ per tonne of liquid CO₂. This innovation delivers exceptional recovery efficiency, even from low-purity gas streams, while reducing operating costs and environmental impact. The result? High-quality CO₂ that meets ISBT and EIGA standards, sustainably.

Benefits

- Water-Free Design: No water consumption during operation, ideal for breweries focused on sustainability.

- High-Purity CO₂: Liquid CO₂ purity ≥99.998% v/v, O₂ ≤5 ppm v/v, meeting ISBT and EIGA standards.

- Exceptional Recovery Efficiency: Even at low inlet CO₂ purity (≥90% v/v), ECO₂Brew achieves superior recovery rates compared to traditional systems.

- Safe & Refrigerant-Free: Uses brewery glycol for liquefaction—no Freon or ammonia required.

- Plug-and-Play Installation: Delivered pre-mounted, pre-wired, and pre-piped on two 40 ft skids for fast setup. Optional containerized outdoor solution available.

- Proprietary CO₂Scrub Technology: Proven in bioethanol applications, now optimized for brewing, removes impurities without water.

- Energy Savings: Up to 40% energy reduction with glycol-heated vaporizer.

- Robust & Reliable: Built for continuous 24/7 operation with uptime ≥95%.

- Handles Challenging Gas Streams: Tolerant to fermentation gases with high adjunct levels.

-

PROCESS DESCRIPTION

-

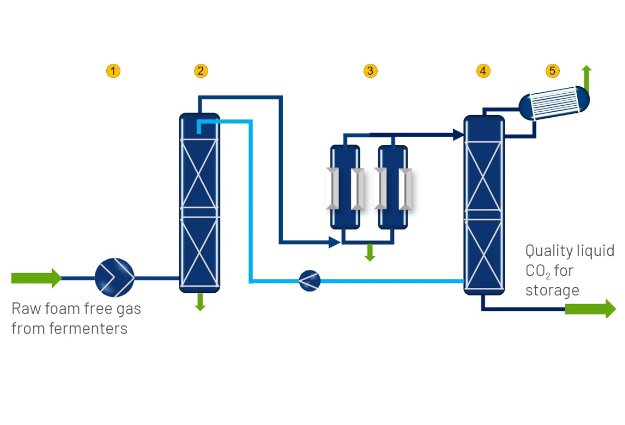

Raw foam-free fermentation gas is fed to the ECO2Brew system, where CO2 screw compressor units (1) increase the gas pressure to 48barg (696psig) in 3 stages, removing condensate in the process. H2S is filtered after the 2nd stage.

The remainder of the impurities is absorbed by liquid CO2 in the specially designed CO2Scrub (2), and purged into the atmosphere.

The water in the gas is removed in the online drier (3) downstream.

Regeneration of the off-line drier is automatic, utilizing heating elements and dry CO2 purge gas. CO2 liquefaction takes place in the glycol-cooled condenser (5), and O2 is removed in the stripper (4).

The flash gas is led back to the 2nd stage of the CO2 compressor, whilst the purified liquid CO2 end product is fed at 15 barg (218 psig) to the onsite storage tank.

-

OPTIONS

-

- Foam separator

- Gas booster

- Gas balloon, gas washer, and dry running 3-stage compressor (alternative to screw compressors)

- Liquid CO2 storage tank

- Ambient or Glycol heated vaporizer

- Cylinder filling unit

- Road tanker pump

- Quality control equipment

- Installation and commissioning services

- Original spare parts

- After-sales services

- Foam separator

Downloads

| D | TITLE | DOWNLOAD PDF |

| Product Leaflet | Haffmans ECO2Brew | Download |

| Case Study | Lion Brewery | Download |

| Technical documentation | Request Product-Specific Technical Documentation | Please, send us your request |

Related products

HAFFMANS CO2 RECOVERY PLANT - CO2MPACTBREW

CO2mpactBrew is a CO2 recovery plant especially designed for smaller, craft-sized breweries with capacity 50.000-350.000 hl/yr.

HAFFMANS CO2 RECOVERY - SYSTEM ENERGY SCAN

Scan your CO2 Recovery Systems with Haffmans and get detailed information on energy consumption, performance and quality.

HAFFMANS CO2 RECOVERY PLANT - CRU

Robust and reliable CO2 recovery solution for a wide variety of brewery needs ranging from 300,000 to beyond 5,000,000 hl/yr.

The analysis of both commercial and recovered gas - an excellent tool to check the performance of the CO2 Recovery Plant.