Medium-rich CO2 streams (PSA off gas), generated from various syngas processes typically found in refineries and petrochemical complexes, is a new alternative for production of food grade CO2.

By utilising an innovative process of combining conventional physical absorption by means of chilled MeOH and CO2 liquefaction technologies, the FlashCO2 process eliminates the requirement for steam stripping while keeping power consumption at an attractive level.

The overall CO2 recovery of the FlashCO2 unit is 92%, 12% more than the minimum required 80%.

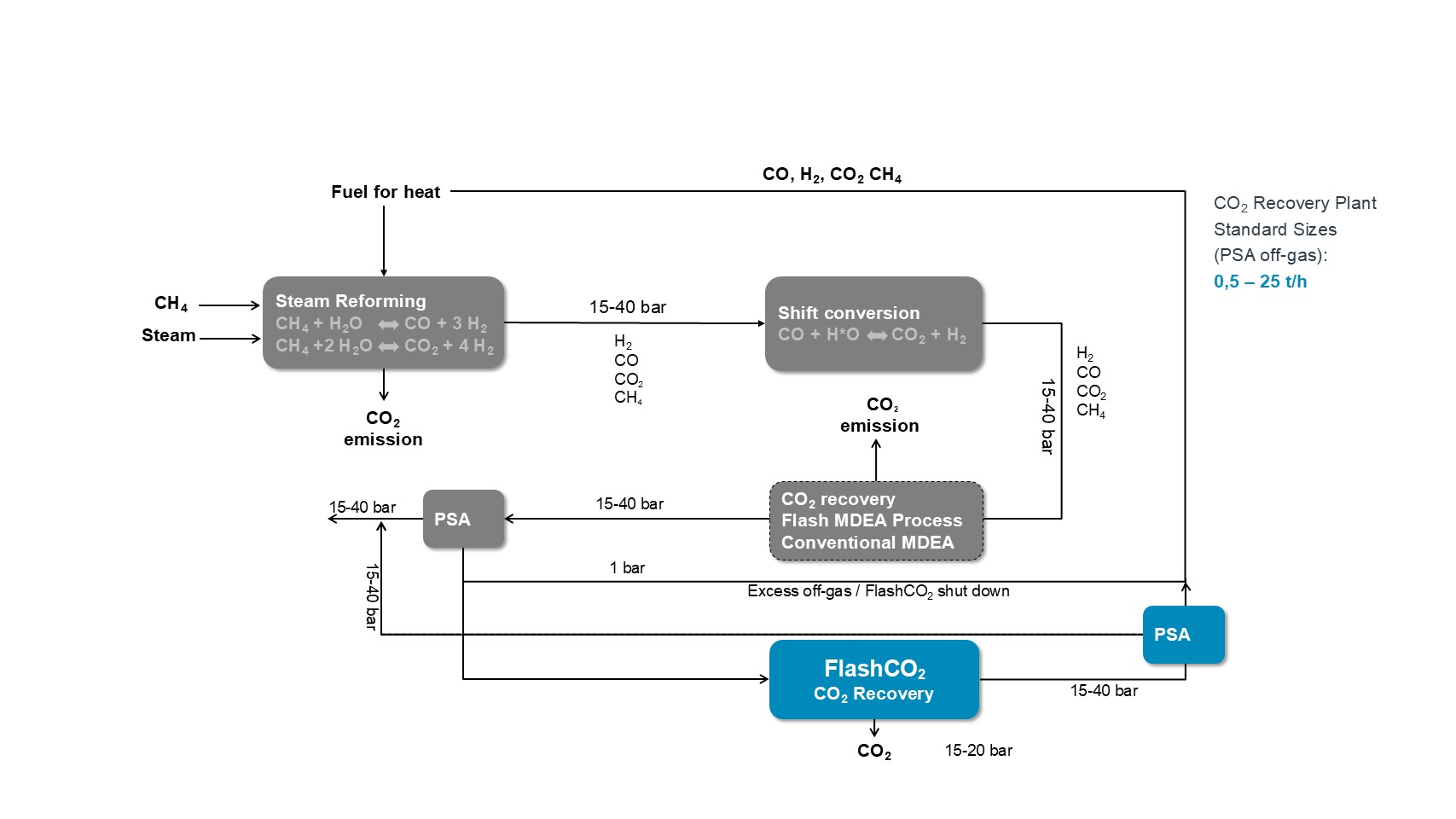

The FlashCO2 technology is a patented process that has been developed for use on Hydrogen plants and steam reformers. The raw gas used is off the gas coming from the PSA and is considered a medium purity raw gas with a typical CO2 concentration of up to 50%. FlashCO2 is developed in order to meet the constraints of installing CO2 recovery plants on Hydrogen plants

Benefits

The potential benefits of using FlashCO2 technology for the removal of CO2 from hydrogen plants compared to Amine technology are:

- When using the FlashCO2 technology, total output from hydrogen production can be boosted to 115% at a low cost

- FlashCO2 technology represents a large-scale option for long-term 2 emissions reduction

- Can reduce greenhouse gases emitted from fossil fuel-based plants

- Liquid CO2 can be produced at a low cost

- Units can be stand-alone

- Other valuable fuel gas products can be recovered from the CO2 process

- Liquid CO2 can be produced at high purity/high-value levels and food-grade quality at low cost

- No effluent treating is required

- No liquid or solid chemical waste

- No steam consumption (flash regeneration of MeOH solvent)

- Low energy consumption (typically 1 GJ/ ton CO2)

- Already installed plants shows that FlashCO2 technology provides a range of advantages, making it a very attractive solution for CO2 capture from hydrogen plants in both the short and long term

-

PROCESS DESCRIPTION

-

One of the challenges is getting access to LP steam, and to cope with the cost. A typical MDEA plant is consuming 1 ton of steam per ton liquid CO2 produced.

Another challenge is that CO2 recovery, based on MDEA, requires complex changes to the existing Hydrogen plant and installation in an ATEX zone, license providers might be reluctant to approve changes in the process. These two challenges were the main drivers when we made the process design for FlashCO2, and accordingly, we have made an ”end-of-pipe” solution where we take the off-gas from the PSA to enter our plant. There is no steam consumption. In principle, the plant can be placed outside the fence of the Hydrogen plant.

One of the real benefits is, that the plant optionally can recover up to 10% extra high-quality Hydrogen by installing an additional PSA. Steam methane reforming is considered the leading technology for the generation of Hydrogen. The reformer is converting methane and steam to syngas that consists of mainly hydrogen and carbon monoxide. Steam reforming is followed by syngas heat recovery that incorporates shift conversion to increase the Hydrogen yield. Finally a Pressure Swing Adsorption (PSA) Unit purifies the raw hydrogen by adsorption CO, CO2, and CH4 gasses.

Downloads

| Title | Download PDF | |

| Product leaflet | Technology for medium-rich CO2 streams - FlashCO2 | Download |

| Technical documentation | Looking for operating instructions, installation manual, spare part list etc.? | Please, send us your request |

Related Products

The Truck Filling Unit is designed for an easy loading and unloading of liquid CO2.