THE COST OF CONTAMINATED BIOGAS

If the methane level of your biogas is too low, or the content of pollutants increases, you may need to use extra energy to upgrade the biogas into biomethane, which can be costly, and in some cases, your system can become damaged.

- Impure biogas can damage your installation.

- If your gas is polluted, this can add to OPEX.

- Polluted biogas causes emissions.

-

WHY SHOULD YOU ANALYZE YOUR GAS?

-

- Get the best value from your biogas production

- Helps with the steady performance of the biogas upgrading performance

- Guarantees the quality of what you provide as a heat source, a biofuel, or a renewable energy source.

-

WHAT THE PROCESS INVOLVES

-

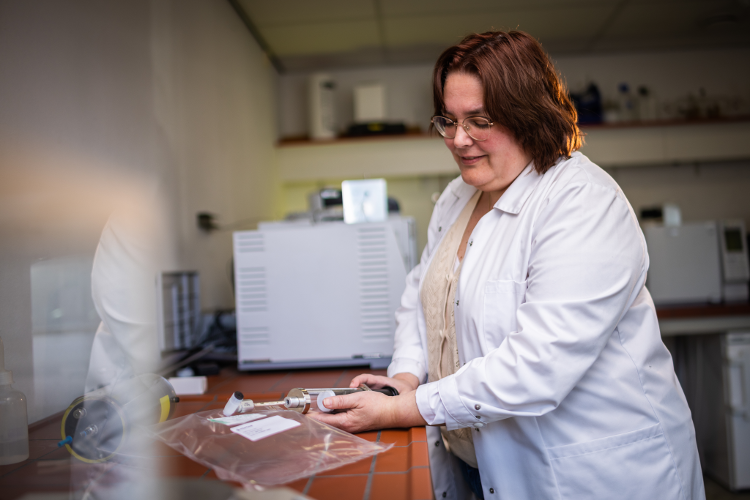

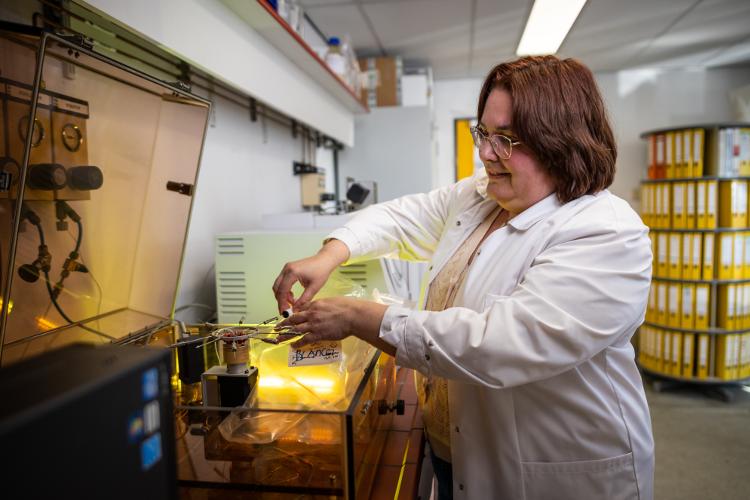

- Protected sample bags with sampling instructions are sent to the customer.

- The customer fills the sample bags and returns the bags to us via Pentair arranged collection.

- An objective analysis report is prepared, specifying measured concentrations of the sample. The report is returned to the customer within five working days.

-

PENTAIR HAFFMANS CAS HELPS WITH

-

- Product control through the detection of unexpected compounds.

- Enables the recovery of food-grade quality CO2 from biogas upgrading.

- Assists in monitoring the performance of biogas digestor or biogas upgrading plant.

- Helps in reducing instances of plant downtime due to contaminants.

- Provides access to Pentair biogas and CO2 recovery expertise

- Product control through the detection of unexpected compounds.

-

GAS ANALYSIS USE CASES

-

- Inlet and outlet biogas generation

- Biogas-to-biomethane generation

- Bioethanol

- Industrial CO2 recovery gas analysis

- Biofuels: Bio-CNG and Bio-LNG

- CO2 from fermentation and breweries and soft drinks

- Gas samples can be taken at the gas source of the product and all points in between

-

WHAT WE TEST FOR

-

- Methane

- Ketones

- BTEX

- Esters,Aldehydes,Alcohols

- Sulphurous Compounds

- Terpenes

- Silonaxes

- Other Organic Compounds

| TITLE | DOWNLOAD PDF | |

| Brochure | CAS for Biogas and Biomethane | Download |

NEWS